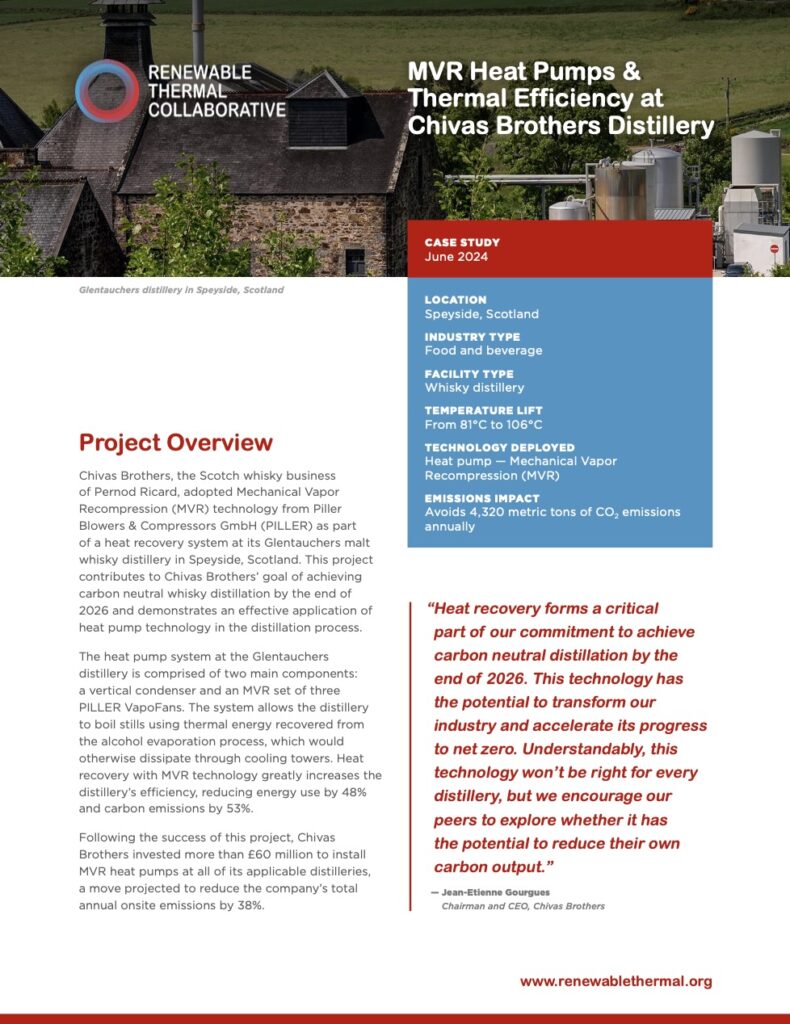

Explore how Chivas Brothers implemented innovative heat pump technology from RTC Solutions Provider Piller Blowers & Compressors at its distillery in Scotland to increase efficiency and reduce emissions. The project uses mechanical vapor recompression (MVR) technology to recover thermal energy from the whisky distillation process, reducing the site’s total energy consumption by 48% and carbon emissions by 53%. The case study explains the heat pump system’s customized design and highlights its successes, which prompted Chivas Brothers to invest £60 million to deploy MVR technology across the rest of its eligible distilleries.

Webinar Recording

The RTC held a webinar diving deeper into this project, featuring experts from Piller TSC Blower Corporation. Click the icon to watch the recording.