By Lynn A. Kirshbaum, Senior Associate, David Gardiner and Associates

Last week, David Gardiner and Associates along with Global Efficiency Intelligence submitted a new report to the Renewable Thermal Collaborative, Electrifying U.S. Industry: A Technology- and Process-Based Approach to Decarbonization. The report consists of a Technical Assessment, an analysis of barriers to industrial electrification and proposals to help overcome those barriers, and an Action Plan that describes what can be done by industry, governments, utilities, and suppliers of electrification technologies or equipment to accelerate the adoption of industrial electrification technologies.

Industrial thermal energy needs, especially for heat, are a significant challenge for climate change mitigation efforts. Worldwide, industrial heat makes up two-thirds of industrial energy demand and almost one-fifth of total energy consumption. However, only ten percent of this demand is met using renewable energy. In the U.S., fossil fuel combustion to produce heat and steam used for process heating, process reactions, and process evaporation, concentration, and drying creates about 52 percent of the country’s industrial direct greenhouse gas (GHG) emissions.

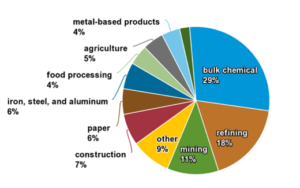

Share of subsectors from total U.S. industrial sector energy use in 2019

Source: U.S. Department of Energy/ Energy Information Administration

There is a significant opportunity to decarbonize the industrial sector by shifting heat production away from carbon-intensive fossil fuels to clean sources such as electrification where low- or zero-carbon electricity is used.

The report’s Technical Assessment analyzes the current state of industrial electrification needs, the technologies available, and the potential for electrification in thirteen industrial subsectors. The subsectors included in this analysis are:

- Aluminum casting

- Paper (from virgin pulp)

- Recycled paper

- Container glass

- Ammonia

- Methanol

- Recycled plastic

- Steel

- Beer

- Beet sugar

- Milk powder

- Wet corn milling

- Crude soybean oil

The total technical annual energy savings potential (with 100% adoption rate) in the thirteen subsectors studied is over 529 petajoules (PJ) per year in 2019, and 663 PJ per year in 2050. This corresponds to annual CO2 emissions reduction of over 134 million tonne (Mt) per year in 2050. That is equivalent to taking 29,000,000 passenger cars off the road for a year.

The report considers various electrification technologies and where they may be applied in the subsectors listed above. These electrification technologies include:

- Electric boilers

- Heat pumps

- Electric arc furnaces

- Induction heating

- Radio-frequency heating

- Electric infrared heaters

- Ultra-violet (UV) heating

- Microwave heating

- Electric induction melting

- Plasma melting

- Electrolytic reduction

In addition to the technical analysis, the report reviews the major technical, economic, market, institutional, and policy barriers impeding the scaled development and deployment of industrial electrification, as well as proposals that could help to overcome these barriers. This analysis of barriers and proposals was informed in part by a survey of industrial energy experts, offering insights into how important identified barriers are to decision making, and how effective proposals may be to overcome these barriers.

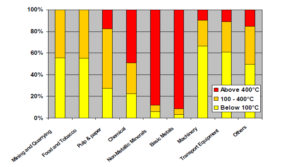

The wide range of specific temperatures and applications required for various industrial processes is one of the challenges of electrifying industry. Different technology types are capable of delivering different temperatures for different applications. Certain technologies may be well suited for particular applications and not for others. This creates complexity for industrial energy users.

Share of industrial heat demand by temperature in selected industries

Source: Caludia, V., Battisti, R., & Drigo, S. 2008. Potential for solar heat in industrial processes.

The lack of reliable information on and familiarity with thermal electrification technologies poses a barrier to increased deployment. Potential users of these technologies may not be aware of the benefits that could be realized, and financing institutions unfamiliar with these technologies may deny needed capital or increase the cost of lended capital to mitigate their own risk.

The report’s Action Plan identifies key actions that industrial companies, governments, utilities, and suppliers of electrification technologies or equipment can take to accelerate the electrification of thermal energy in industry. Key recommendations include:

- The industrial sector should:

- Initiate partnerships with academia, national labs, think tanks, and other stakeholders to develop or scale electrification technologies.

- Work with stakeholders to educate policymakers, utilities, and financial institutions about the benefits of electrification and what policy, regulatory, and financial support is required to electrify industrial processes.

- Provide training for employees and contractors about electrified technologies. Government and utilities should support such training programs.

- Governments should:

- Provide incentives for electrification technology development and demonstration and use the capacity at the U.S. Department of Energy (DOE) national labs to advance electrification technologies for industry.

- Work with utilities to provide financial incentives in the form of tax credits or grants for pilot projects and demonstration of emerging electrification technologies in industry.

- Conduct techno-economic analysis for all electrification technologies applicable to industrial subsectors.

-

- Adopt a variety of policies and programs to support industrial electrification.

- Utilities should:

- Evaluate the demand response (DR) potential that increased electrification in the industrial sector can provide to utilities and its financial implications.

- Provide information about their electric rates, market structures, and grid upgrade implications of industrial electrification.

- Adopt electricity rate designs that encourage electrification.